Airflow data example 2

Airflow data example 2

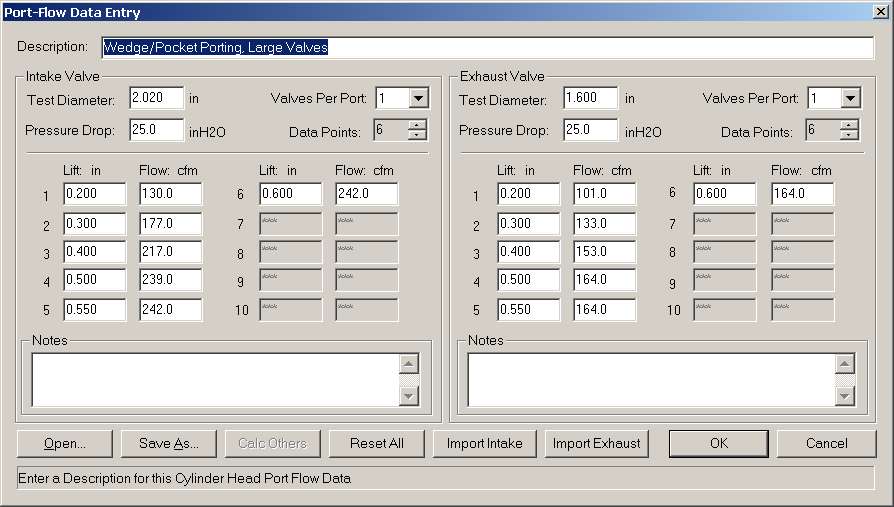

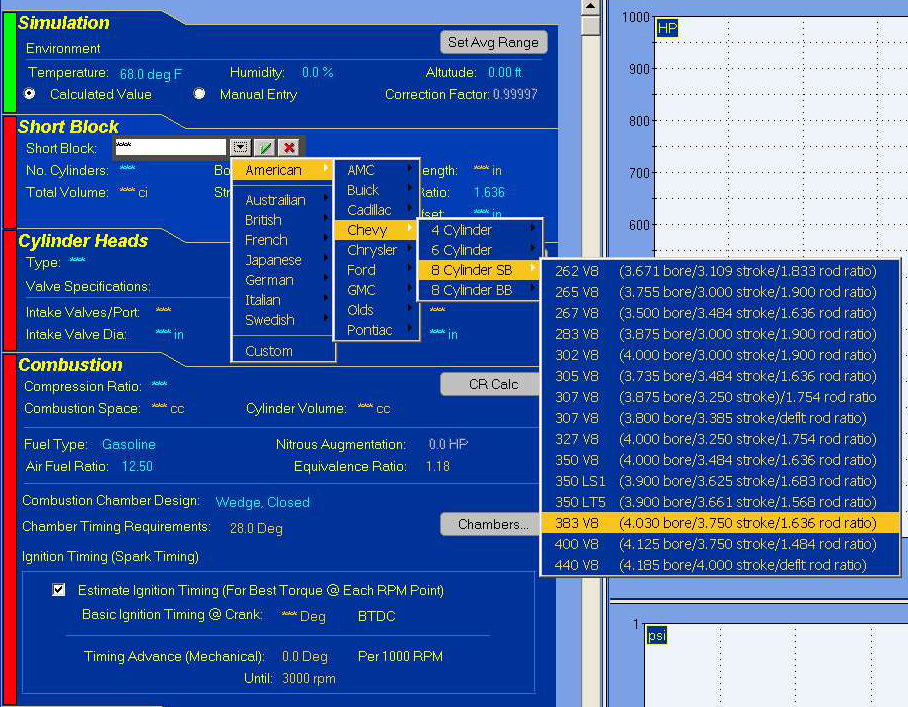

First, we select the engine bore and stroke in the dyno software. Next, we start providing information on what heads will be used. There are some generic selections for stock heads of different types with several levels of porting or valve head diameters that will simulate differences in airflow. We can also input directly your airflow numbers if we have taken them. There are several aftermarket head selections within the software to see what improvements different heads could make. Whether we use your stock heads or you buy aftermarket heads, we can test the airflow of the heads used and save those numbers to the dyno software for a more accurate simulation.

This is a good time to introduce the idea of airflow in the engine. Have you ever heard the phrase “an engine is nothing more than an air pump?” For the most part, the more air an engine can move through itself, the more power it will make. This is measured as “volumetric efficiency.” While not running, when a piston is positioned at the bottom of a cylinder, BDC, with the intake valve open, atmospheric pressure will fill the cylinder to 100 percent capacity. (fig. 1) That would be 100 percent volumetric efficiency. While an engine is running, especially at higher rpm's, it is hard to get the cylinder 100 percent full. Average volumetric efficiency may be in the 85 to 93 percent range on a street performance engine but as high as 115 percent on a NASCAR Sprint Cup engine. The more air-fuel mixture in the cylinder when it fires, the more power it will make. This is also why more cubic inches make more power.

Moving air through an engine efficiently is a science, which involves coaxing the air through ports, around curves, and through restricted valve openings. (Air won’t bend more than 15 degrees at a time without separating from the surface and causing turbulence.) The bigger is better theory doesn’t always apply. Huge ports and runners work with big cubic inch engines or at high rpm's but hurt smaller cubic inch engines and low rpm. Big ports and runners cause the airflow to be “lazy” as if it isn’t supported by enough volume being drawn. There is a balance of flow and velocity to be maintained to achieve the best overall performance and drivability. The best port or runner design for a head or intake manifold, is one that flows the highest volume of air at the highest velocity. Don’t get me wrong, more flow is needed to make more power. Gaining airflow in an engine can add an additional 2 horsepower per cfm of airflow. Just don’t go so big that you have lazy airflow.